Spare Parts Manufacturer ERP System Case Study

- Industry: Manufacturing

- Location: Singapore

Introduction

Tntra engineered a top-level ERP software system for a globally leading spare parts manufacturer. The current system of clients needed to be updated, making it difficult to streamline processes across different departments. This cost the company revenue and made the processes time-consuming. Tntra developed a custom application that helped the client improve its operational efficiency and online customer experience by building nine different modules in the ERP system.

As a leading software engineering company, Tntra was in a strong position to deliver the clients a custom application that could help the client enhance its interoperability and improve its operational efficiency.

Keep reading to find out more about how Tntra helped the spare parts manufacturer with the development of a custom ERP system.

- Django

- Web Development

- Software Testing

- Support & Maintenance

Business Problem

The client wanted to boost order fulfillment by enhancing their 3PL supply chain solutions. They sought to build global warehouse visibility and incorporate Industry 4.0 for warehouse automation.

The ERP system was outdated and lacked seamless communication capabilities, making it difficult to streamline processes across different departments. This cost the company revenue and made the processes time-consuming.

Without any third-party integrations in the existing system, the manufacturer was limited to the in-built functionalities of the older system.

The client also faced issues storing and displaying the gathered information to internal and external users.

Project Goal

- To digitally transform the company and replace manual processes with electronic methods.

- Automation of routine processes to speed up the work and reduce the chances of human error.

- Improve communication amongst the teams and enhance effective collaboration efforts.

- Implementing statistical algorithms and machine learning techniques to optimize processes and forecast inventory movement.

- Capturing data with deep understanding to analyze information and make better-informed decisions.

- Create a user-friendly and easily accessible platform for greater reach and create online revenue streams.

- Integrating inventory systems across alliances of companies to help strengthen the supply chain and networking capabilities.

Solution

- Tntra developed an internal portal for staff to manage day-to-day activities. The internal portal is company-specific and is used by all the companies affiliated with the client.

- We also developed an external portal for consumers to make online purchases and track their orders. The internal portal manages the online store as a module by the company in charge.

- The ODOO-based enhanced ERP platform delivered a top-notch customer experience, catering to the self-service preferences of the consumers.

- We developed an integrated inventory system that bolstered the supply chain and networking capabilities across their alliance of companies.

- We integrated predictive analytics through statistical algorithms and machine learning techniques to optimize processes and forecast inventory movement.

- Tntra automated the business processes to speed up operations and reduce errors.

Business Impact

- Tntra helped the client to increase harmony between departments. The new ERP system led to a 3x reduction in the time to manage business functions across all departments.

- A superior customer experience was provided by the ODOO-based upgraded ERP platform, which catered to the consumers' demands for self-service via a user-friendly platform.

- The new ERP system enables the integration of third-party applications, which has helped with the augmentation of the logistics and warehouse processes for the client.

- The digitization of analog records and automation of processes helped in improving the manufacturers' productivity and reduction in errors.

- The client optimized processes and inventory forecasting by leveraging predictive analytics and machine learning.

- Seamless communication and accurate data storage were established to help the company reduce internal miscommunication and enhance credibility.

Features

Have a look at the top features that our developers incorporated into the solution.

Inventory Management

This platform acts like a product catalog for SKUs captured on manufacturers SAGE database. It enables the staff to easily search for SKUs, their description, photos, brochure resources, specifications, stock availability, pricing, and more.

Purchase Management

ODOO-based ERP platform streamlines companies purchases into a centralized hub, simplifying tracking and management of all procurement activities efficiently.

Order Management

The order management platform consolidates all orders coming in from ERP, OES, and the store, while allowing staff to manage the entire order process.

Pricing

The ERP systems also store price lists for all price codes along with the special support prices. It also helps in the approval process of any action that involves product pricing.

Warehouse Management

The ERP system displays information from the Warehouse Management System on the Order Management System to help track incoming and outgoing orders, quality control, and more.

Logistics Management

This ERP system is designed in such a way that it can integrate seamlessly with third-party logistics platforms to monitor delivery and collection jobs.

Customer Portal

Serving the self-service preferences of the consumers, we built an online store that was integrated into the ERP system.

Accounts ManagemenT

The system helps in managing the transactions with the vendors and the customers. It ensures accurate recording, tracking, and reporting of monetary transactions.

Tntra Diamond

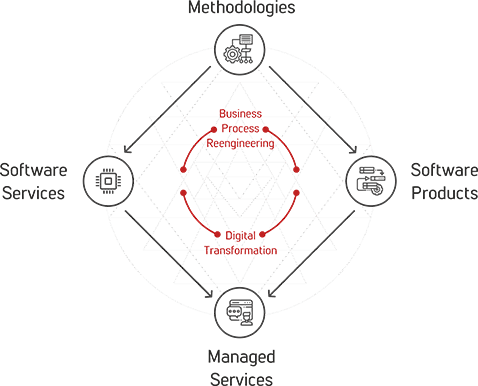

Tntra's Diamond is a comprehensive approach to helping enterprises manage the constant interplay between Business Process Reengineering and Digital Transformation. Tntra’s domain specific methodologies lead to software services for mature systems and software product engineering for new requirements, further transitioning to a managed service model to ensure stability and scale.

Tntra's Diamond enables the enterprise to stay ahead of the transformation curve, while at the same time ensuring optimal business processes to meet the needs of the new economy.