Optimizing Inventory and Waste Management with Technology Consulting Solutions

Table of Contents

ToggleTechnology consulting solutions for waste reduction and inventory management involve assessing a company’s current processes and systems for managing waste and inventory, identifying areas for improvement, and integrating suitable technologies to optimize the process. Implementation of tech consulting has numerous benefits in managing inventory and controlling the wastage of stock.

Walmart is among the world’s biggest retailers and is known for its “Everyday Low Prices” slogan. The company operates a wide variety of stores, including discount department stores, supercenters, supermarkets, and neighborhood markets.

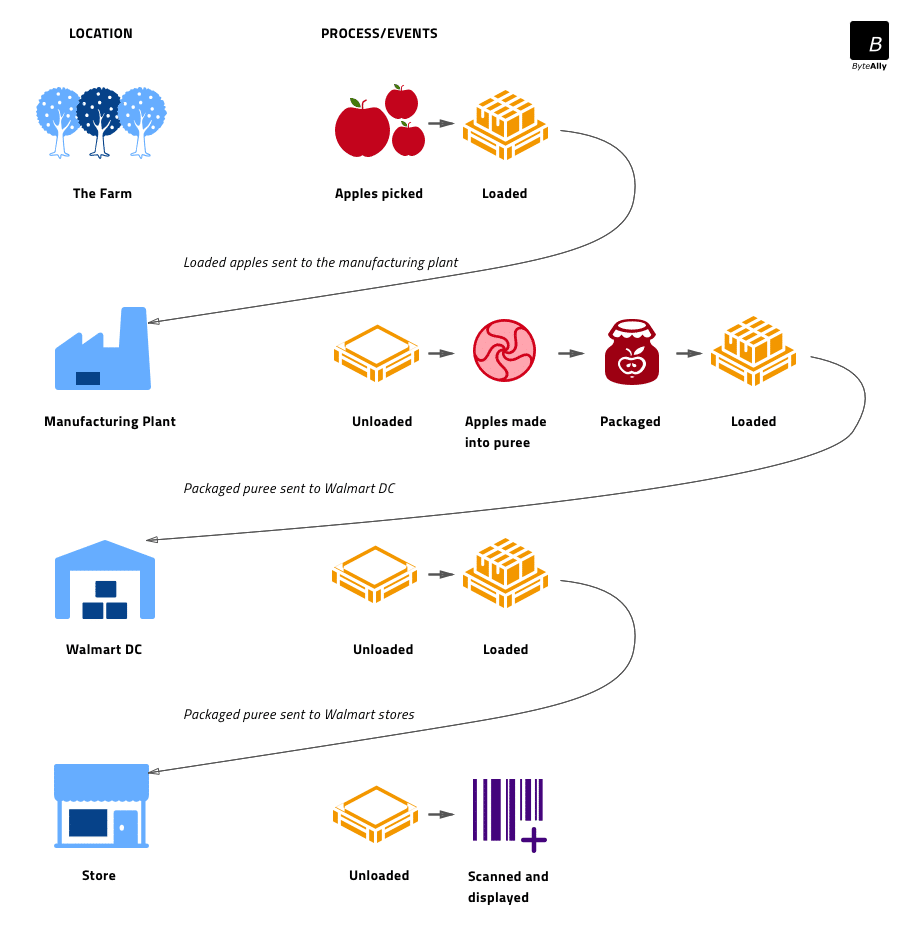

In 2010, Walmart successfully met its goal of a 15% reduction in food wastage. However, with time food waste continued to increase due to greater demand for fresher items. In response to this, Walmart resorted to technology consulting solutions to digitize its food supply chain.

To improve its supply chain in the long run, the company worked with IBM to avail of its technology consulting services. IBM used Blockchain technology to allow food products to be traced to their origins to let the Walmart staff trace back the contaminated food item. In 2017, Walmart unknowingly pulled healthy lettuce off shelves. With Blockchain technology in place, this event can be avoided.

Walmart has adopted techniques such as Hyperspectral imaging which helps them to identify internal damage to the food items allowing ease with the sorting process at the warehouse. In addition, the supply forecasting solutions enabled by a software product engineering company have helped Walmart to work with the farmers and prevent harvest failures. Using these models, Walmart can supply farmers with fertilizer or crop protection applications to protect against crop quality concerns.

Source: Harvard

Global Inventory Stockouts and State of Inventory Management

The global cost of inventory distortion, such as shrinkage, stockouts, and overstock, is projected to be at $1.1 Trillion. The high price also entails the large quantity of inventory that has gone to waste over the years. The inefficiency of the inventory management process can lead to such losses.

43% of small enterprises in the United States agree to not tracking inventory, or either doing so using a manual system. Yet, tracking inventory levels is crucial for avoiding stock outs which can lead to delays in order delivery. Software product engineering services can provide digital solutions to help prevent stockouts and waste management.

The demand for more transparency in the supply chain is on the rise. This results from achieving more control over waste management objectives across businesses. Therefore businesses are seeking inventory management solutions to track the items more accurately. However, the average U.S. retail business has an inventory accuracy of only 63%. Inaccurate inventory forecasts can still lead to wastage and stockouts.

A professional technology consulting company like Tntra can build custom software platforms for businesses to track their inventory for achieving efficiency in the supply chain and thus reducing wastage.

Read more: Trends Transforming the Technology Consulting Industry in 2023

Pressing Issues in Inventory and Waste Management

Inventory and waste management are crucial for business operations, yet many companies face challenges in these areas.

Inventory Management Issues

- No Real-Time Tracking: Businesses often experience stockouts or overstocking due to the inability to track inventory in real time. This results in lost sales, increased holding costs, and operational inefficiencies.

- Neglect in Demand Planning and Forecasting: Poor demand forecasting leads to excess stock or stockouts. When businesses fail to forecast demand effectively, they either accumulate surplus inventory and incur high storage costs or have insufficient stock and miss potential sales.

- Manual Processes and Errors: Tracking and reporting manually can lead to human errors. Mistakes in stock levels or order quantities can disrupt operations, cause delays, and impact customer satisfaction.

Waste Management Issues

- Overproduction and Expired Stock: Excess production can result in expired stock, particularly in the food and pharmaceutical industries. This not only leads to financial losses but also contributes to environmental waste.

- Environmental and Regulatory Concerns: Companies face increasing pressure to comply with stringent waste management regulations. Failure to adhere to these regulations can result in fines and reputational damage.

- Waste at Scale: Without the right data and calibration mechanisms, tracking and reducing waste becomes highly challenging. Identifying waste sources and implementing effective solutions requires data-driven strategies.

Technology Consulting Solutions for Inventory Management

Technology consulting services offer advanced solutions to tackle inventory management challenges.

- Real-Time Tracking with IoT and RFID

IoT (Internet of Things) and RFID (Radio Frequency Identification) technologies enable businesses to track inventory in real time. With sensors and RFID tags, companies gain visibility into stock levels, reducing errors and improving storage efficiency. - AI and Machine Learning for Demand Forecasting

AI and Machine Learning (ML) enhance demand forecasting by incorporating historical data and market trends. Using predictive algorithms and deep learning models, these tools optimize inventory levels, reduce waste, and enhance customer satisfaction. - Cloud-Based Inventory Management Systems

Cloud-based technology consulting solutions provide centralized inventory tracking, real-time visibility, and automated processes such as reordering. These systems help businesses minimize manual errors, optimize operations, and make data-driven decisions while allowing for scalability and remote access.

Technology Consulting for Waste Management

Emerging technology consulting helps companies track waste, adhere to sustainability goals, and improve operational efficiency.

- Data Analytics for Waste Management

With data analytics, businesses can analyze production data to identify inefficiencies. Companies can then implement targeted strategies to reduce waste and enhance sustainability. - Blockchain for Traceability and Compliance

Blockchain technology ensures transparency and accountability in waste disposal. It allows businesses to track waste from production to disposal, ensuring regulatory compliance and environmental responsibility. - Automation and Robotics in Waste Management

Automation and robotics streamline waste management processes, minimizing human error, increasing operational efficiency, and improving recycling rates. These technologies help businesses reduce total waste and improve sustainability.

Advantages of Technology Consulting for Inventory and Waste Management

Partnering with an enterprise technology consulting firm offers several benefits:

- Tailored Solutions: Technology consulting services develop customized strategies to enhance inventory accuracy and minimize waste.

- Cost Reduction: Automation and streamlined processes lower operational costs and improve efficiency.

- Sustainability and Compliance: Technology consulting solutions help businesses meet regulatory requirements and achieve sustainability goals more effectively.

By leveraging technology consulting for inventory management and waste management strategies through tech consulting, businesses can improve operations, reduce costs, and drive sustainable growth.

Impact of Technology Consulting Solutions on Inventory and Waste Management

Technology can play a key role in inventory and waste management in optimizing processes and increasing efficiency. Software product engineering solutions provided by engineering companies such as Tntra can help businesses track the status of each and every item in their inventory.

The custom solution assisted by Tntra technology consulting can include implementing inventory management software, integrating inventory management with other business systems (such as enterprise resource planning (ERP) or customer relationship management (CRM) systems), and implementing barcode scanning or other data collection technologies.

Here are a few more potential benefits of using technology consulting for inventory management. Here are some examples:-

1. Technology Consulting Solutions Helps in Reducing Storage Cost

- Technology consultants provide the benefits of inventory management by focusing on inventory planning and reducing storage costs. In addition, implementing technology can help identify inefficiencies in inventory management processes and reduce waste, which can help a company control costs and improve profitability.

- Proper inventory management also helps in lowering the cost of storage and thus helps in the increment of revenue. Therefore, it is essential to emphasize technology consulting for inventory management.

2. Technology Consulting Solutions Help in Better Decision Making

- WMS design consultants can help in building inventory and waste management systems that provide enough transparency for accessing a single, centralized view of inventory levels in multiple warehouses in different locations.

- The real-time view of inventory data and analytics helps business leaders quickly identify trends and patterns that can inform their decision-making. It helps predict future demands, optimize stock levels, and minimize waste.

3. Technology Consulting Solutions Help in Maintaining the Product Quality

- Tntra is one of the top technology consulting firms that can develop custom inventory and waste management solutions to control and manage business efficiency and product quality. The benefit of such technology consulting services is eliminating waste generation and focusing on the appropriate Right First Time or Six Sigma Quality.

- If you wish to retain your hard-earned customers and want them to keep coming back to you, technology consultants can help you with solutions that help to maintain the quality of your products and services.

Checkout Our Case Study on Freight Forwarding and ERP System

Conclusion

Technology consulting provided by Tntra can offer significant benefits to businesses of all sizes. By assessing your company’s current inventory management processes and recommending and implementing new technologies, our consultants can help you to optimize its inventory management and improve efficiency, accuracy, decision-making, customer service, cost control, scalability, and visibility.

Implementing automation, data analytics, and real-time inventory tracking can lead to better inventory control, lower costs, improved customer service, and better waste management, leading to increased competitiveness and profitability.

With Tntra technology consulting, businesses can make data-driven decisions and respond to market changes more quickly and efficiently by using technology consulting for inventory management and waste control.

Tntra provides IP-led product engineering to mentor, collaborate, develop, partner, and successfully deliver innovative services on a global stage. In addition, our engineers can help you with simple yet effective custom technology consulting for your supply chain and inventory management.

Consult team Tntra today.

1. Why do businesses need tech consulting for waste management?

Tech consulting helps businesses implement advanced solutions like data analytics, automation, and blockchain to track, reduce, and manage waste efficiently while ensuring regulatory compliance and sustainability.

2. How to optimize inventory with technology consulting?

Technology consulting leverages AI, machine learning, IoT, and cloud-based systems to improve demand forecasting, automate inventory tracking, and minimize waste, ensuring optimal stock levels and reduced holding costs.

3. How does technology consulting improve inventory tracking?

With real-time tracking technologies like IoT and RFID, businesses gain better visibility into inventory movement, reduce errors, prevent stockouts or overstocking, and enhance overall supply chain efficiency.